A 157 Year Old Consumer Packaged Goods Company

Organizing business teams around value to improve supply chain operations.

Company Introduction

The visionary Director of Supply Chain was looking to apply the SAFe Framework to their process improvement business teams. Specifically, they were looking to:

Execute their business initiatives using right-sized Scrum teams working in 2-week iterations.

Align the teams’ priorities for Q1 to ensure that the teams were working on the most valuable things.

Run planning sessions to identify and manage the dependencies between teams and plan out the work for each quarter.

Take a pragmatic approach to get started quickly and improve as they learn.

And by quickly, they meant in 2 weeks! An ambitious plan? Yes.

But the options were either that, or wait until the next quarter to get started. And as any agilist will tell you, “never put off to tomorrow what you can start learning from today”. And learn we did!

The Opportunity

This project presented a unique opportunity to apply SAFe® to process improvement teams. With the recent release of SAFe® 5.0 and its focus on Business Agility, we were anxious to apply a framework that is traditionally applied to software solutions to non-digital solutions.

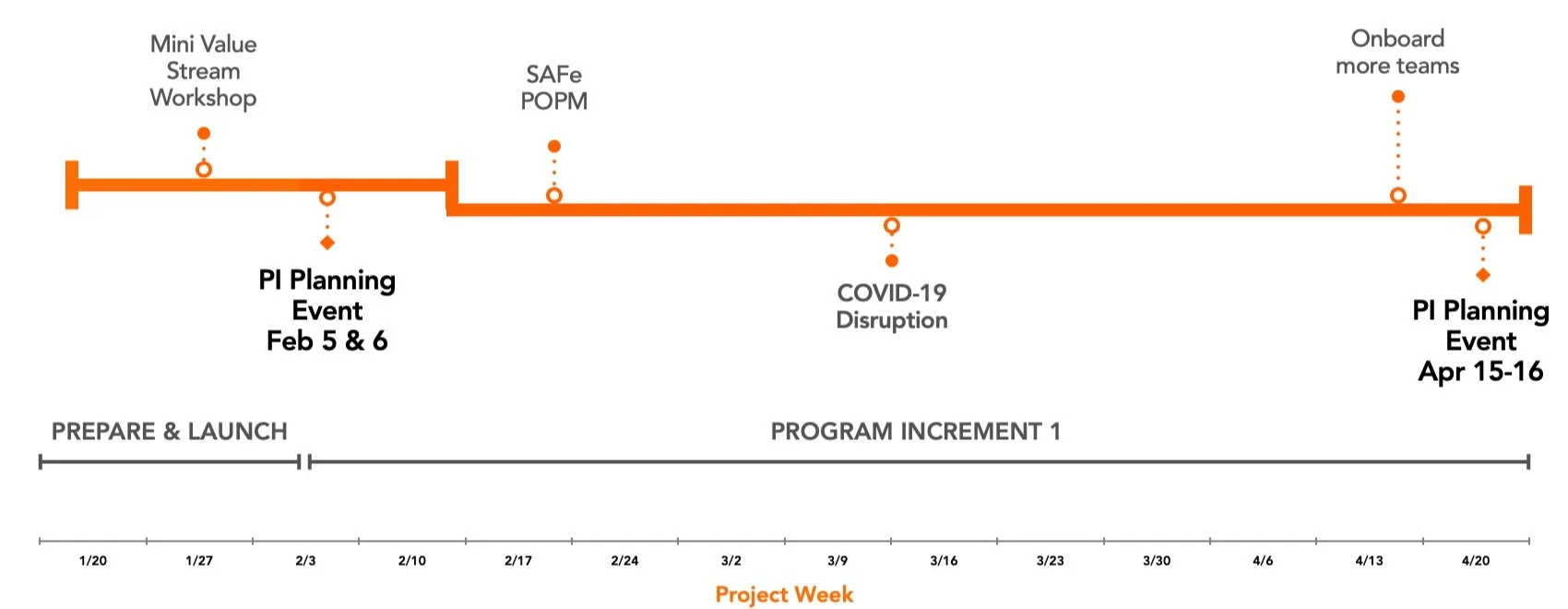

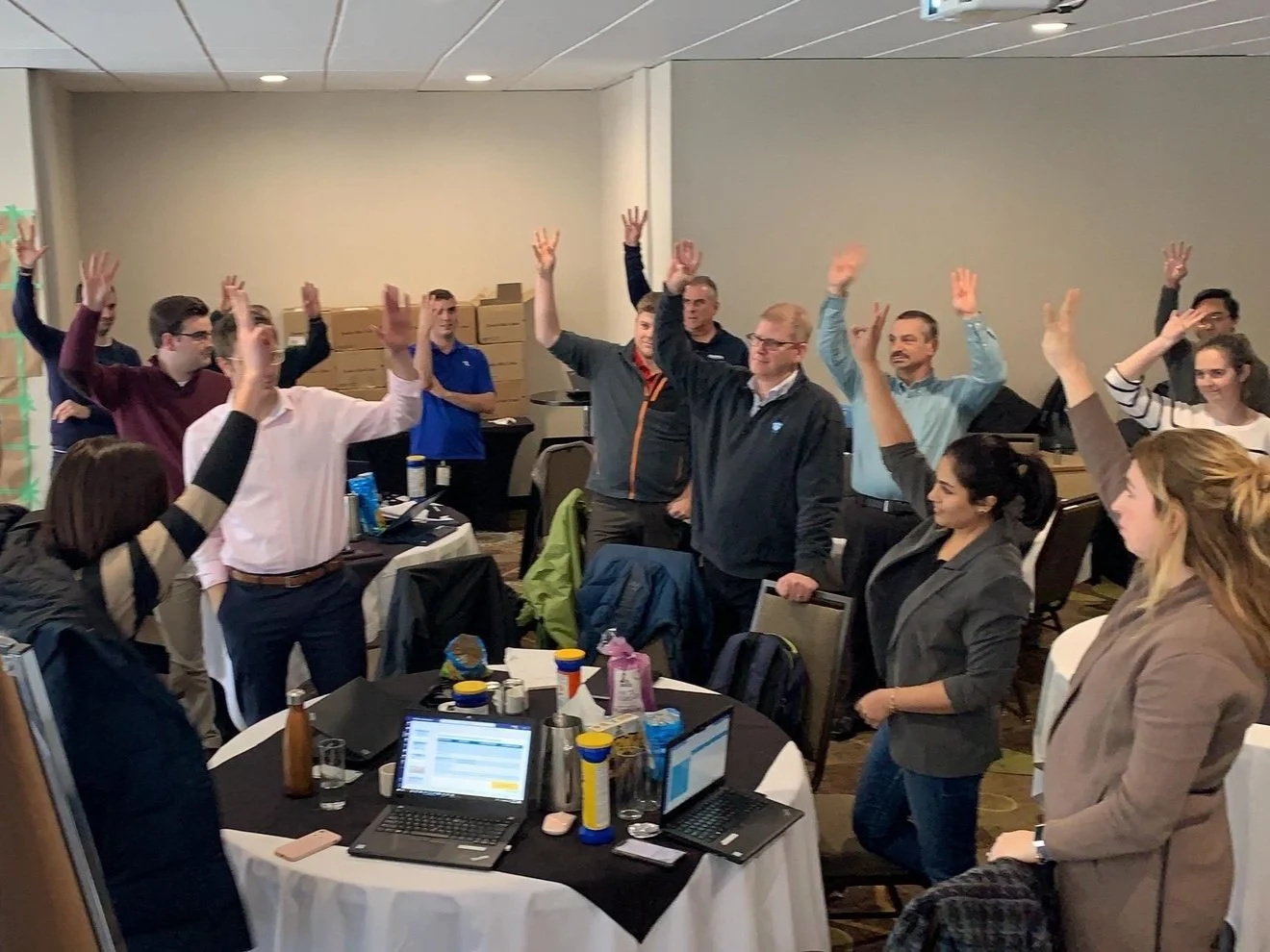

The project was also our fastest ART launch ever. With great client leadership and experienced coaches, we organized quickly and successfully launched a single ART with 5 teams and 70 people in a little over 2 weeks. The teams left the 2-day Program Increment Planning Event with clear objectives and high confidence.

That was February 6th, 2020. Five weeks later, in the middle of their 3rd iteration, North America would essentially be shut down. All industries were impacted, and food production companies were identified as critical.

The pandemic response pulled people away from their previously planned work. The teams are very close to the Front Line. As a result, some of them had to change focus completely in response to COVID-19. This meant abandoning their original Features and PI Objectives and using that capacity for completely different work.

Our Timeline

Our Solution

The teams responded to the disruption by relying on the Lean-agile principles they learned in SAFe® Scrum Master and SAFe® Product Owner / Product Manager courses taught by Springbach, along with coaching and their own experience with Lean Six Sigma. Leadership stayed the course on minimizing WIP and prioritizing work so the teams knew where they needed to focus.

The teams were in crisis and and some of them completely abandoned the Scrum events. However, the ART events, including the System Demo were retained. While some might consider abandoning the Scrum events to be a bad thing, the results demonstrated at the PI System Demo spoke for themselves.

There were a number of successes. More importantly, judging from the conversations in the Demo and the Inspect & Adapt workshop, it was clear that the teams continued to follow these principles:

Worked together daily

Shortened feedback loops

Minimized WIP

Welcomed changes

The results

Real business results were achieved. At the end of the first 12-week Program Increment, the following results were demonstrated (remotely, of course):

-

Changes to the ERP system and new standard operating procedures which reduced time to enter data and reduced variability in the data that is entered so that responses to customer complaints about issues with delivery can be managed better and root causes identified.

-

New product ideas continued to be pursued with Suppliers. The new product ideas moved through the mandatory joint-approval steps faster than their previous approach.

-

Automated Excel process which saves a team of 2 people 1.5 person-hours per day in analysis time.

-

The team working on in-store displays was able to support the client’s sudden change in advertising (due to COVID-19) to focus on comfort, in-home consumption, and ads without people.

Improved the way the BOMs (Bill of Materials) are calculated and audited. The BOM’s are now more accurate, allowing for more accurate purchasing of raw materials and product pricing.

-

Created a new process for managing orders. Customer orders are now processed based on previous orders rather than a simple first-in- first-out approach. This change was not insignificant, and it allowed the client to proactively control how food was distributed across all of Canada during a time when food distribution was critical.

Furthermore, this change also modernized how the client determined when a product might not be available. In the past product stock-outs were determined at the loading dock; now product stock-outs are recognized before the trailer is ordered, leading to reduced shipping costs and higher utilization of transportation resources.